Introduction

In recent years a lot of progress has been made to produce sustainable alternatives to plastics for essential applications, such as “Great Wrap”, a potato-based alternative to Cling Film, or “Chitofoam”, a packaging material made from Mealworm exoskeletons. In this blog let’s explore the Impact of Edible Packaging prepress. sustainable packaging is the still early-stage Edible Packaging concept.

A sub-category of sustainable packaging is the still relatively early-stage Edible Packaging concept. Though it is still in the early stages of its mass use. The concept of edible packaging as a viable alternative to plastic film is no longer a fringe idea. It has serious advantages over bioplastic packaging. For one, the jury is still out about what actually happens to bioplastic in landfills.

One concern is that biodegradable plastics in landfills may not actually degrade the way we think1. For another, some researchers and designers believe that the carbon in bio-packaging when released into the atmosphere will create CO2 buildup2. Edible packaging of course, has no such concerns since it is meant to be consumed by people or animals, which won’t just reduce pollution, it could even marginally offset food demand, especially for livestock. However, edible packaging manufacturing has a major problem to overcome- sustainable and safe printing.

The Packaging Prepress Process

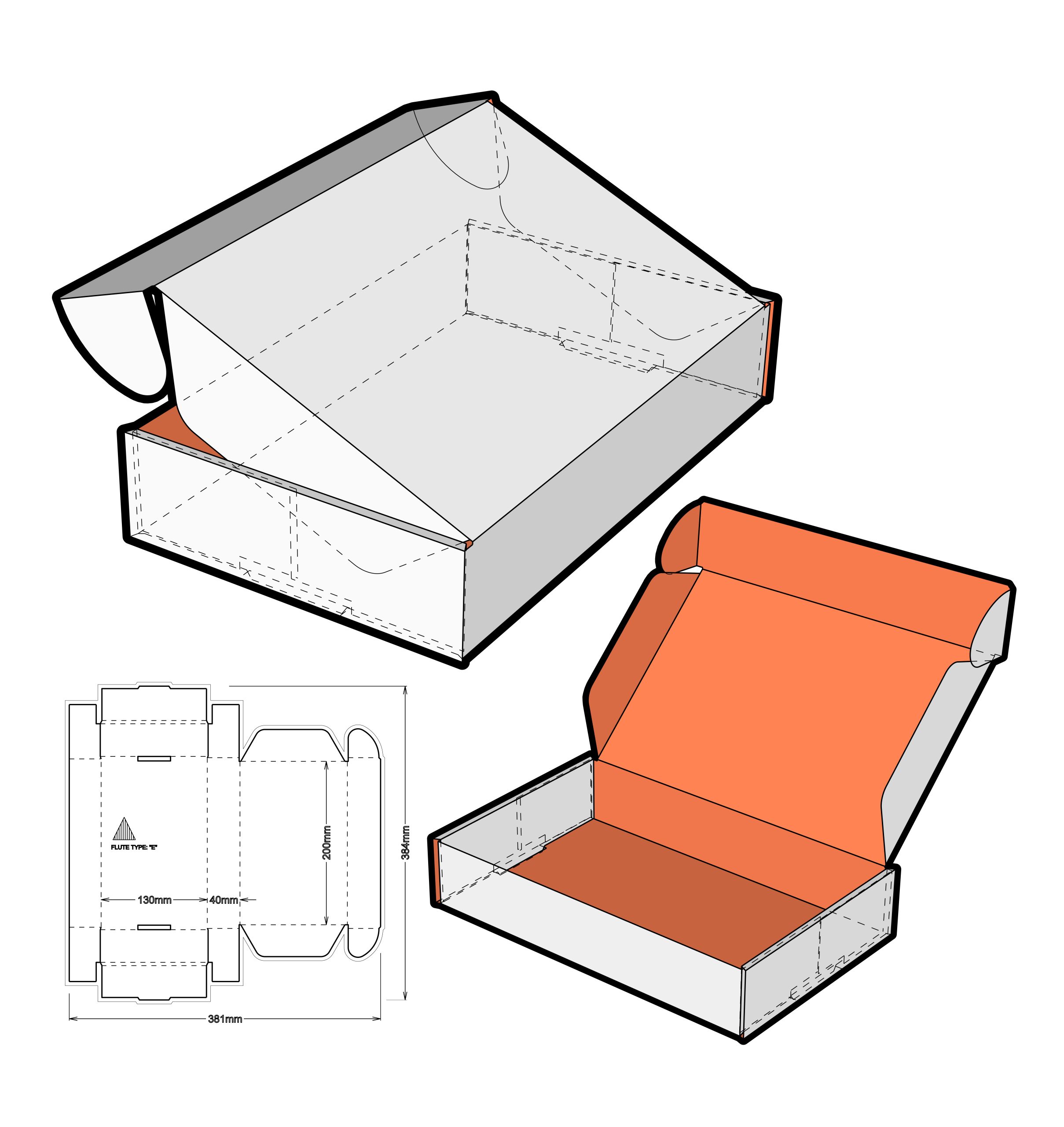

For decades on-package printing has been an essential part of the manufacturing process. Colors, graphics, branding, and information are all packed onto packages in attractive, eye-catching ways. As a result the packaging prepress process is deeply embedded into the packaging value chain. One of the most important tasks for a prepress graphic artist is to understand the properties of the packaging substrate (the material the artwork is printed on such as paperboard, clear plastic, metal, etc.), the printing press, the inks etc. and then perform tasks like dot removal, trapping, Pantone replacement, Repro, etc.

However, edible packaging is a different story. After all, edible packaging is meant to be consumed by people or animals and must therefore use food-grade materials for both substrate and artwork printing. Therefore the packaging prepress artists must learn to work with an entirely new class of packaging materials, printing processes, inks, and pre-press techniques.

Edible Packaging Specific Challenges

The difficulty of doing packaging prepress on edible packaging has several factors. The major ones are:

- The type and properties of the edible material used for packaging

- The type and properties of the printing ink used for edible packaging are different than traditional printing inks

- The type and properties of the printing method used for edible packaging has to be suitable to the material

Materials-related issues- Edible packaging can be made from a very wide variety of sources, such as seaweed; starch from potatoes, cassava, corn; proteins from plant, animal, and dairy sources; fruit skins; crustacean shells; gelatin; sugar; algae; agar; and mushrooms, to name just a few! Each material has unique properties, and combining two or more materials creates even more variations.

Printing Method & Ink- Laser, Inkjet, and direct 3D Printing are new methods that will play a major role in edible packaging printing. However, large scale will still use one of the traditional stalwarts- Offset, Flexo, and/or Gravure. Each of these is suitable for only a few of the many edible materials out there. For example, Gravure may work well with Potato Skin substrates. While Flexo will be much better for Seaweed due to the thinner, more brittle substrate qualities.

The point is, the role of the Prepress artist is changing. We see that going forward Prepress experts will work much more closely with design firms and brands to identify the right materials, right printing techniques, as well as the right prepress workflows to optimize between various constraints and objectives.

Conclusion

Obviously these well-known problems have no easy answers. One reason for this is that new materials are being invented daily. As these become more mainstream. The proper pairing of printing ink based on natural inert pigments, edible dyes, or consumption-friendly nanoparticles will develop slowly.

For years packagers have focused on making packaging engaging, because engagement is an important step towards purchase. Most appeal improvement efforts focus on improving visual appeal. some packagers have even used texture, “scratch & smell”, and embedded speakers to engage buyers’ other senses. Prepress artists were involved in each of those groundbreaking endeavors, and that will also happen for edible packaging. When they succeed, they will help create a paradigm shift in marketing where edible strips will let buyers “taste before purchase”, and tactile elements will literally people to play with their food!